How to make a soaring bed with your own hands, stages of work

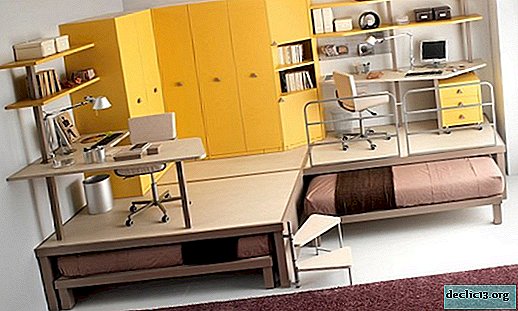

To create an original interior in the room, various fashionable novelties are used. The highlight of the bedroom will be a flying bed, comparing favorably with standard models. Do-it-yourself airy weightless soaring bed is made of available materials. Before developing a drawing, you need to familiarize yourself with the nuances of work in order to avoid common mistakes.

What is a

The sleeping bed, hovering in the air, despite the apparent weightlessness, is a strong, reliable, stable product. The flight effect is created due to the lack of familiar legs. As a support, a single leg is used, which is invisible under the bed. The LED illumination located under the sleeping bed gives a beautiful view to the product. Furniture with a peculiar design has its own pluses, minuses, features. Modern models are characterized by the following advantages:

- Original stylish design. After installing the product in the bedroom, its interior will become unusual.

- Comfort. As a rule, such beds are made with a large berth.

- Fastening strength. The product is simultaneously attached to the wall and floor, so it does not stagger.

- Accessibility of the area under the bed. Using a mop, you can easily wash inaccessible areas.

An original piece of furniture, if desired, can be made with your own hands from inexpensive materials in individual sizes. However, the unusual sleeping bed has some disadvantages:

- complex manufacturing, requiring certain skills in working with wood, plywood, metal;

- lack of boxes under the berth for storing things;

- difficulty moving furniture to another place.

But these shortcomings are fully paid off by the beauty and originality of the subject for sleep and relaxation.

Drawing up a design project

Before work, you need to prepare a drawing of a soaring bed for making it yourself. First you need to determine the dimensions of the furniture being created, choose the necessary material, decide which parts will be included in the design, clearly present the appearance of the future product.

If there is not enough experience or the necessary equipment, then some of the parts should be ordered from specialists. This applies to metal supports and the frame of the product. Together with the materials, it is necessary to give the master detailed drawings, which must be completed in full accordance with the standards of the future product.

The first step is to view photos of the finished models and select the appropriate option. Attention should be paid to the materials from which the furniture is made, dimensions, additional elements used for decoration. To determine the size of the unusual design, you need to make accurate measurements of the room in which the bed will be installed. Then it is supposed to choose a mattress, the layout of furniture with the effect of levitation will also depend on the dimensions of which.

After determining the width and length, the question is solved with the dimensions of the support. It is better to look at the furniture from the greatest distance and sketch. Only then can you finally choose the size of the support, decide how much less it should be done relative to the main part of the structure. It should be noted that the support should not be narrow, otherwise the bed will swing.

There are options for models that do not require support. In this case, the flying structure has a headboard of large thickness and an L-shaped steel pipe, a short length of which is firmly fixed to the wall. The frame is made strong enough not to sway or break even when sitting on the edge of the bed. It is possible to manufacture an intermediate version with a smaller support made of a high-strength transparent, almost invisible material.

Then, the configuration and size of the headboard is selected, which is one of the main parts of the design and determines the design of the bed. The color of the product and decorative elements are considered. Next, a scheme for a soaring bed is drawn up, and structural elements, joints, and parts that are used for reinforcement are worked out. In the process, you need to more often check the results, measure the details several times, in order to exclude a possible error at the initial stage, and not at the end of the product.

The drawing is made both for the entire structure, and for the details. For precise manufacturing, not one, but several projections are performed. At the end of the drawing of the plan, you can proceed with the acquisition of materials and tools.

Materials and Tools

For self-made beds are materials that must have a high degree of wear. First of all, this is wood, which is the main raw material for the production of any furniture.

Wood grade | Characteristic |

Pine | It is resistant to decay due to the large number of resins. It is easy to work with a pine, it is well processed. It is used for power parts - legs, frame. Not suitable for decorative elements, as it is poorly painted. |

Spruce | The characteristics are similar to pine, but its strength is less, the wood can crack. Serves for parts that are not subjected to high loads. |

Beech | The tree is light yellow or pinkish in color, characterized by good flexibility. It is suitable for supporting parts and decor. It will take enough time and effort to process the wood. |

Oak | Durable material that will last a long time. It is ideal for creating power and decorative furniture parts. Oak is difficult to process. |

Larch | Popular wood has strength, durability, resistance to decay. Suitable for the production of support and frame products. |

Red tree | It has many varieties of varieties. Rare expensive wood, used for decorating external elements and decorating the bed. |

To save the budget, instead of a natural tree for external elements, you can use chipboard panels.

To complete the furniture frame, not only wood is used. Pipes made of steel with a cross-section in the form of a square are perfect for these purposes. They are durable, light, they are easy to process and connect with each other. Since the bed is subjected to heavy loads, it is better to use steel pipes, rather thick.

If you plan to create a soft headboard, then in addition to wood and metal, filler and upholstery material will be required. In the first case, foam is used, as well as similar materials. The second uses different types of leather and textiles.

For the manufacture of the product, it is necessary to prepare the following components:

- a sheet of wood measuring 200 x 20 x 2 cm;

- metal steel pipes or bars of wood of the desired parameters;

- plywood sheet for the base of the frame;

- LED strip, which will require approximately 7 m;

- boards with locks, they are installed on the side of the frame and the head in the amount of 4 pcs.

The process of creating a floating bed with lighting requires the following tools:

- drill;

- hacksaw or jigsaw;

- screwdriver;

- self-tapping screws for assembly;

- level;

- stubs;

- rubber mallet;

- roulette;

- marker;

- hammer;

- screwdriver;

- supplies for painting.

All fittings are selected in accordance with the colors of future soaring furniture.

Manufacturing steps

On how to make a soaring bed with your own hands, there are many videos and articles. They will help even a novice to deal with the intricacies of the assembly of individual parts. Installation consists of several stages.

Building a frame of wood and metal

Creating a frame requires special responsibility, since the product's life and durability depend on its quality. Manufacturing steps:

- Room preparation. Usually the creation of the bed takes place in the bedroom. Before starting work, you should remove all objects from the room, and cover the remaining ones.

- Start assembling the support from metal parts or thick boards. The frame from 3 sides should be less than the edge of the sleeping bed by a maximum of 30 cm.

- Transverse components are installed along the frame, inside the contour, the distance between which is 30-50 cm.

- At the bottom of the structure, you can install patch elements for the legs.

- Brackets for bolts are fixed on the support.

- At all angles located inside, columns are installed connecting the supporting part and the bed.

When the frame is built, you can begin to manufacture the next element.

Bed support box

Bed support box Furniture corner

Furniture corner Crossbars

Crossbars The connection of the support and the box

The connection of the support and the box Metal frame

Metal frame Reinforcement corners

Reinforcement cornersFrame creation

The frame is needed to place a mattress on it, the headboard is also fixed here.

- The outer part of the structure is assembled from wood.

- The frame is complemented by longitudinal and transverse details to enhance and maintain shape.

- If you plan to use LEDs, then the power supply is installed.

- The frame and the support are connected.

- Both parts are processed with sandpaper and then varnished.

- A wooden board or plywood is placed on the frame.

- On all sides of the frame, external borders are fixed, treated with stain or painted.

When performing a metal construction, the principle of operation is the same, only with the use of other tools and fixtures. In this case, welding, cleaning products from sagging, grinding of sharp corners will be required.

Bed frame

Bed frame Connecting the frame to the support

Connecting the frame to the support Plywood sheet

Plywood sheet Outboard

Outboard Soaring wooden bed

Soaring wooden bedHeadboard

The algorithm for performing all the work looks like this:

- A plywood piece or OSB plate is fixed on the frame, on which the marking is applied.

- Glue on the plate is fixed foam rubber, synthetic winterizer, holes for buttons are made.

- A material is pulled onto the filler, the size of which is taken with a small margin.

- Buttons are inserted into the holes, sewn tightly with strong threads.

The finished headboard is connected to the frame and frame.

LED backlight setting

To enhance the effect of flight, an LED strip is laid around the perimeter of the product. The stages of its installation are not difficult.

- Check the tape for defects by connecting the power supply to the network.

- If during the assembly of the product the site for installing the block was not equipped, then it should be placed in an inconspicuous place.

- The protective film is removed, the LEDs are glued under the frame.

- The power supply is located in a specially prepared place.

Hovering bed with backlight, made by hand, requires patience, time, experience. The result is a strong, comfortable, beautiful product that will decorate the bedroom and create a special aura in the room.